Kalibraatio – How Smart Calibration Can Transform Your Business!

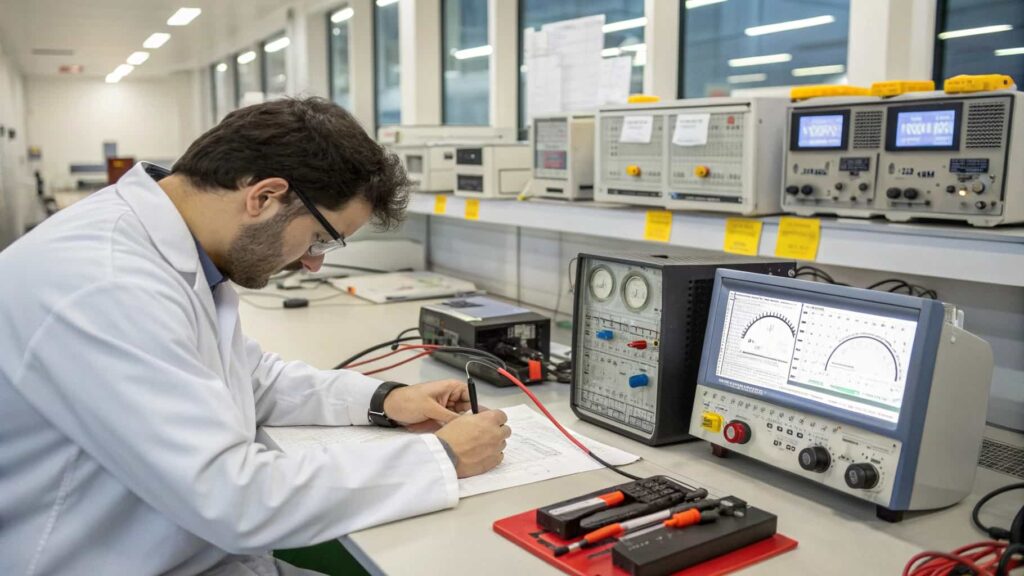

In today’s fast-paced industrial and technological landscape, precision is not just a luxury—it is a necessity. Kalibraatio, or calibration, is the process that ensures instruments and equipment deliver accurate, reliable, and consistent measurements.

Whether in healthcare, manufacturing, or environmental monitoring, the implications of incorrect readings can range from costly inefficiencies to serious safety risks.

This article explores the world of kalibraatio, highlighting its importance, key methods, industry applications, and practical strategies businesses can use to ensure accuracy and excellence.

What Is Kalibraatio And Why Does It Matter?

Kalibraatio refers to the adjustment and verification of measurement instruments against known standards. Its purpose is simple but critical: to minimize errors and guarantee that readings reflect true values.

Accurate measurements form the backbone of almost every industry. For instance:

- In healthcare, miscalibrated devices could lead to incorrect diagnoses or treatment plans.

- In manufacturing, even minor deviations can produce defective products, causing financial loss and damage to brand reputation.

- In environmental monitoring, imprecise data can hinder responses to pollution or public health concerns.

By prioritizing kalibraatio, businesses ensure operational integrity, enhance safety, and foster trust with clients and regulatory authorities.

The Role Of Kalibraatio Across Industries – Why Precision Matters Everywhere!

Calibration isn’t one-size-fits-all; each industry applies kalibraatio according to its specific needs.

Healthcare and Medical Devices:

Precision in healthcare is literally a matter of life or death. Medical equipment such as infusion pumps, blood pressure monitors, and imaging devices must undergo rigorous calibration schedules. Even slight deviations can compromise patient safety, treatment efficacy, and hospital compliance with health standards.

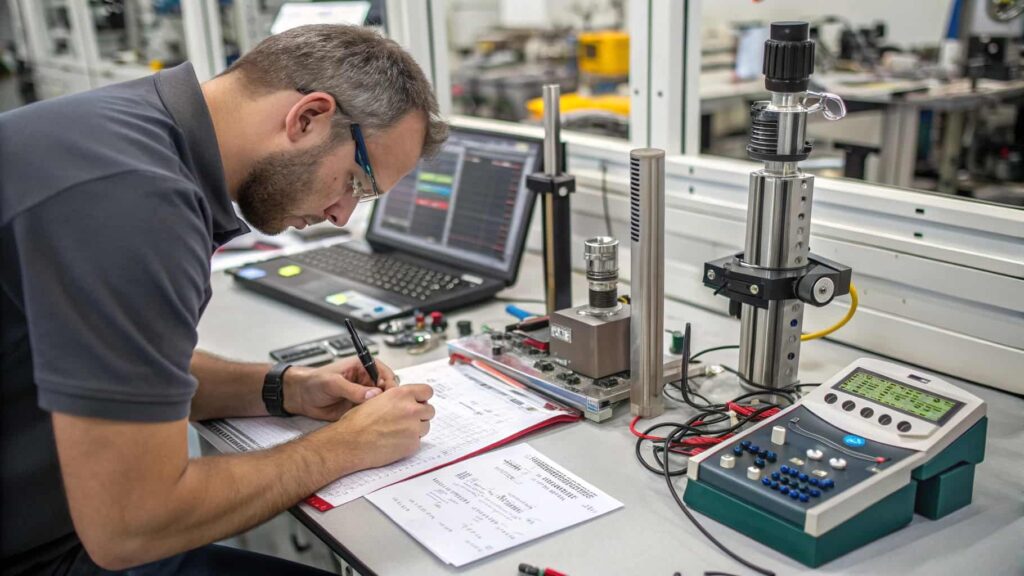

Manufacturing and Industrial Production:

In manufacturing, calibrated equipment guarantees product quality and operational efficiency. Machines operating off-specification can lead to:

- Defective products

- Increased downtime

- Wasted materials and higher costs

Regular kalibraatio ensures production lines maintain consistent standards and minimizes the risk of costly recalls.

Food and Beverage Industry:

Temperature, pressure, and volume measurements are crucial in food processing. Accurate calibration guarantees food safety, compliance with health regulations, and consistency in flavor and texture. In industries where consumer trust is paramount, proper kalibraatio is a cornerstone of quality assurance.

Environmental Monitoring:

Air quality sensors, water testing instruments, and climate monitoring devices require precise calibration. Reliable data allows for effective pollution control, early warning systems, and informed policy decisions to safeguard public health.

Technology and Electronics:

High-tech industries, including semiconductor manufacturing and electronics testing, rely heavily on kalibraatio. Even minor measurement errors can compromise product performance, functionality, and innovation outcomes.

What Are The Main Benefits Of Proper Kalibraatio?

Investing in regular calibration brings multiple advantages that go beyond simple measurement accuracy:

- Enhanced Accuracy: Correct readings ensure processes and products meet precise specifications.

- Operational Efficiency: Accurate equipment reduces the need for rework or adjustments, saving time and resources.

- Safety Assurance: Calibration minimizes risks associated with faulty readings in critical systems.

- Extended Equipment Lifespan: Regular checks identify wear early, preventing costly breakdowns.

- Regulatory Compliance: Adhering to industry standards maintains certifications and avoids legal penalties.

- Trust and Reputation: Consistency and reliability strengthen relationships with clients and stakeholders.

Which Methods Are Commonly Used For Kalibraatio?

The approach to calibration depends on the type of equipment, required accuracy, and operational context. Common methods include:

Reference Standard Calibration:

Using a device or material with a known value as a benchmark, technicians adjust the equipment to align with that standard. This method is ideal for high-precision laboratories and industrial processes.

Comparison Calibration:

In this method, an instrument is compared against a high-precision device. Differences are noted, and adjustments are made accordingly. This is common in on-site industrial applications where absolute reference standards may not be practical.

Field Calibration:

Technicians perform adjustments on-site without removing the instrument from its operating environment. This reduces downtime and ensures operational continuity, particularly in critical industries like manufacturing or utilities.

Software-Based Calibration:

Modern instruments often include software algorithms that automatically refine measurements. This approach can reduce human error and improve speed, though it may require validation to ensure accuracy.

Self-Calibration:

Some devices include internal calibration mechanisms, allowing users to perform routine adjustments independently. While convenient, these methods should be complemented with periodic professional checks to maintain compliance.

How To Choose A Reliable Kalibraatio Service Provider?

Selecting the right service provider is essential for maintaining equipment accuracy. Consider the following factors:

- Certifications and Accreditations: Providers should comply with international standards like ISO/IEC 17025.

- Industry Experience: Expertise in your sector ensures the provider understands unique calibration needs.

- Customer Reputation: Reviews and testimonials provide insights into reliability and service quality.

- Service Range: Comprehensive providers can calibrate multiple types of equipment under one roof.

- Response Time and Support: Fast turnaround minimizes operational disruptions.

By carefully vetting service providers, businesses ensure long-term reliability and consistent compliance with regulatory standards.

Why Is Kalibraatio Essential for Industry Compliance?

Staying compliant with industry standards is not optional. Many sectors have strict requirements governing calibration frequency, documentation, and precision. Proper kalibraatio helps businesses:

- Avoid legal or regulatory penalties

- Maintain certifications essential for competitive advantage

- Enhance operational efficiency through systematic maintenance

- Build trust with clients and regulators

Documentation plays a vital role. Detailed calibration records demonstrate commitment to quality and provide audit trails for inspections.

What Are The Latest Trends In Kalibraatio?

The world of calibration is evolving with technological advancements. Businesses must stay aware of emerging trends:

IoT-Enabled Calibration:

Smart sensors can self-monitor performance, alerting operators when recalibration is required. This predictive approach reduces downtime and ensures continuous accuracy.

Automation and AI:

Artificial intelligence is being integrated into calibration processes, analyzing data trends and suggesting optimal adjustments. This minimizes human error and enhances precision.

Cloud-Based Calibration Records:

Digital platforms allow secure storage and easy access to calibration data, improving audit readiness and process transparency.

Remote Calibration:

With increasing connectivity, some instruments can now be calibrated remotely, reducing the need for on-site technicians and enabling global standardization.

Sustainability-Focused Calibration:

Industries are beginning to incorporate environmental considerations, optimizing calibration schedules to reduce energy consumption and minimize waste without compromising accuracy.

Challenges In Maintaining Proper Calibration – Avoid These Costly Mistakes!

Despite its importance, many organizations face obstacles in implementing effective kalibraatio:

- High Costs: Regular calibration may seem expensive, particularly for small businesses.

- Complex Equipment: Some instruments require specialized expertise and tools.

- Downtime: Taking equipment offline for calibration can disrupt operations.

- Lack of Awareness: Some industries undervalue calibration until errors occur, risking safety and compliance.

Overcoming these challenges requires strategic planning, investment in technology, and partnerships with reliable service providers.

Tips For Effective Kalibraatio Management – Best Practices You Can’t Miss!

- Create a Calibration Schedule: Establish routine checks based on manufacturer recommendations and industry standards.

- Maintain Accurate Records: Track all calibration activities, including dates, results, and adjustments.

- Train Staff: Ensure employees understand the importance of calibration and proper handling procedures.

- Use Certified Equipment: Start with devices that meet recognized accuracy standards.

- Audit Regularly: Conduct internal audits to verify calibration consistency and adherence to protocols.

FAQs:

How often should equipment be calibrated?

The frequency of kalibraatio depends on the equipment type, industry standards, and how often the instrument is used. Critical tools may need monthly checks, while others may only require annual calibration. Regular scheduling prevents unexpected errors.

What happens if I ignore kalibraatio?

Ignoring calibration leads to inaccurate results, higher chances of defects, and potential safety hazards. Over time, it can result in financial loss and regulatory penalties. Businesses that skip calibration risk damaging their reputation.

Can kalibraatio be performed on-site?

Yes, field calibration allows technicians to adjust devices at their operating location. This reduces downtime and keeps operations running smoothly. However, certain instruments may still require laboratory-grade calibration for higher precision.

Is self-calibration reliable for sensitive instruments?

Some devices come with built-in self-calibration functions, which are helpful for routine adjustments. However, sensitive or regulated instruments still need professional calibration. Self-calibration should never replace certified verification in critical industries.

Can digital technology improve kalibraatio processes?

Absolutely, technologies like IoT, AI, and cloud systems are revolutionizing calibration. They allow predictive maintenance, automated adjustments, and remote monitoring. These tools make calibration faster, smarter, and more reliable.

Conclusion:

kalibraatio is not just a technical step but a key to accuracy, safety, and trust in every industry. By keeping equipment properly calibrated, businesses can avoid costly errors and improve efficiency. It also helps maintain compliance with industry standards while protecting both people and processes.

Regular calibration may seem small, but its impact is huge in the long run. Prioritizing kalibraatio today means building a stronger, safer, and more reliable future for your business.

Also Read: